About us

Medathenna Minarals PVT (LTD) has been a unique trendsetter in providing superior quality of Ordinary & Special Medathenna skim coat, Medathenna Calcite powder and Medathenna Dolamite powder here in Horana Industrial zone since 2010. We employ approximately 100 Employees in several areas, Together with our exceptional people and strong stakeholder relationships, we commit to the highest standards of quality, productivity, sustainability and performance that drive our customers value and long-term success, and one of the fastest growing skim coat producer in Sri Lanka. We believe in only producing high quality skim coat and Calcite and Dolamaite powder, crushing Calcite and Dolamite in our factory, and making skim coat by adding polymer and white cement to sell our customers at a fair price we distribute skim coat specially Kalutara, Panadura, Balangoda, Mathugama areas and several district in our country when required.

Future Plans: We are starting to sell the amount of 50 metric tons per month for first three months. Later it is planned to developed until 100 metric tons per month within one year period. And hope to achieve up to 200 MT per month towards that.

We started this business because We have discovered the main problems of skim coat are mixing related problems and application related problems as

- Difficult to trim

- poor workability

- poor mixing

based on the comments given by the retailers and users about skim coat products available at the market. So, we believed there had to be a better way of making skim coat with excellence workability. You only get one chance to make a first impression. Smooth, clean surfaces on exterior and interior walls put everyone in a good mood. The versatility and durability of skim coat have made them a popular choice for both interior and exterior surfaces on a wide range of substrates.

Skim coat must meet certain physical and technical requirements if they are to function properly. Although there are no international standards defined for skim coat yet, we set their own specifications in accordance with local conditions, such as climate, applications, techniques and, local construction codes.

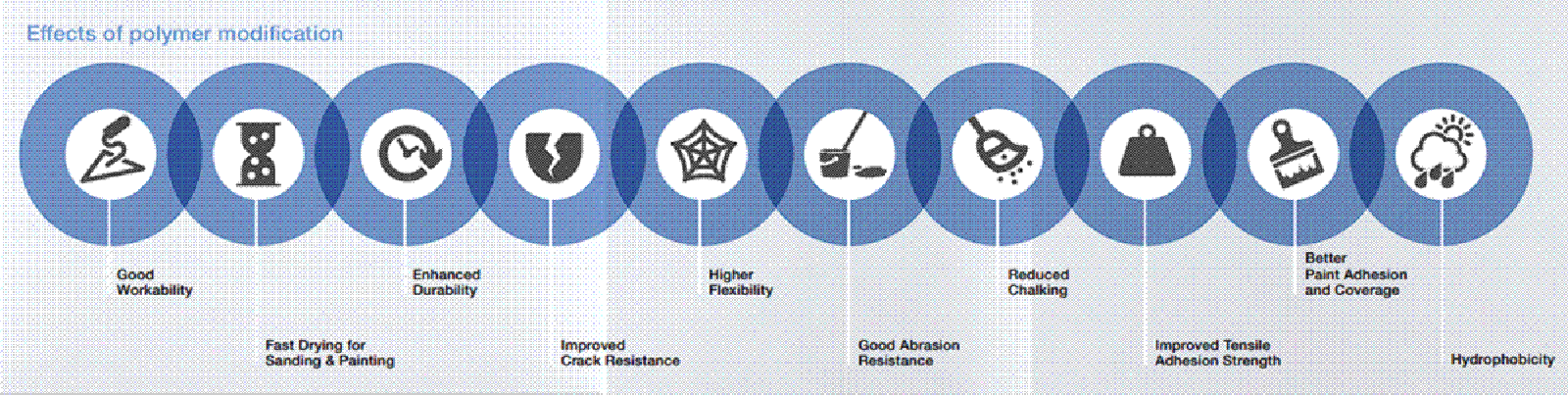

Polymer modification makes it possible to formulate high-quality skim coat that not only benefit applicators in terms of application, but also provide an aesthetic finish which is durable and long-lasting. We produce high quality skim coat by mixing cellulose polymer to our product which fascinate with following features.